28

Jun 2023

How to Bend an Underfloor Heating Pipe

Underfloor heating (UFH) systems provide effective and cosy warmth throughout a space, and ideal performance depends on the appropriate installation. Bending the pipes to match the shapes of the space is one component of UFH installation that could call for some technical expertise.

In this blog article, we’ll provide a step-by-step procedure for bending an underfloor heating pipe to help you complete the installation and distribute heat effectively.

Step 1: Gather the Required Tools and Materials

Before you begin bending an underfloor heating (UFH) pipe, gathering the necessary tools and materials is essential. Here’s a detailed list of what you’ll need:

- Pipe for underfloor heating

- Bending tool or spring for pipes

- Pipe cutter or a well-bladed utility knife

- Measurement ruler or tape

- Hot air blower or a heat gun

By gathering these tools and materials beforehand, you’ll be fully prepared to bend the underfloor heating pipe effectively and efficiently during installation. Remember to prioritise safety and accuracy while working with these tools to ensure a successful UFH system installation.

Step 2: Measure and Mark The Pipe

Once you have gathered the necessary tools and materials, the next step in bending an underfloor heating (UFH) pipe is to measure and mark the desired bending point accurately. Follow these detailed instructions to ensure precise measurements and markings:

- Measure the length of pipe: Use a measurement ruler or tape to determine the length of pipe required for the bend.

- Mark the bending point: Once you have determined the correct length, use a permanent marker or adhesive tape to mark the exact spot where the pipe should be bent.

- Provide support: Before proceeding with the bending process, ensure the pipe is appropriately supported.

By carefully measuring and marking the bending point, you can ensure that the UFH pipe will fit accurately into your wet room’s layout and configuration.

Step 3: Prepare the Pipe for Bending

After measuring and marking the bending point on the underfloor heating (UFH) pipe, the next step is to prepare the pipe for bending:

- Choose the appropriate cutting tool: Depending on your preference and the available tools, you can use a pipe cutter or a sharp utility knife.

- Align the cutting tool: Position it perpendicular to the pipe, aligning it with the marked bending point.

- Cut: Apply steady pressure using the pipe cutter or utility knife to make a clean cut at the indicated bending point.

- Check the cut: After cutting, inspect the pipe end to ensure it is clean and free of debris or burrs.

Making a clean, straight cut at the indicated bending point is crucial for achieving a secure and leak-free connection in the UFH system.

Step 4: Apply Heat

After preparing the underfloor heating (UFH) pipe for bending, the next step is to apply heat to the specific portion that requires bending:

- Select a suitable heat source

- Position the heat source

- Circle the heat source

- Heat small sections at a time

- Monitor the pipe temperature

- Test the pipe’s flexibility

Remember to exercise caution throughout the heating process to avoid overheating, melting, or damaging the pipe. By carefully applying heat and gradually softening the pipe, you can achieve the desired bend without compromising the structural integrity of the UFH system.

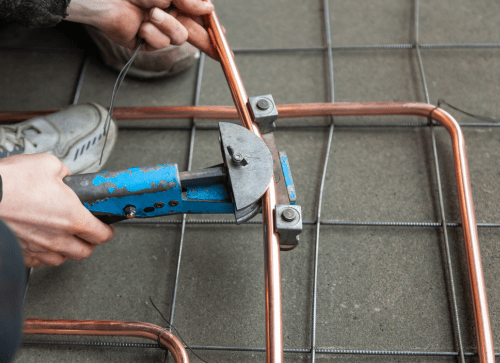

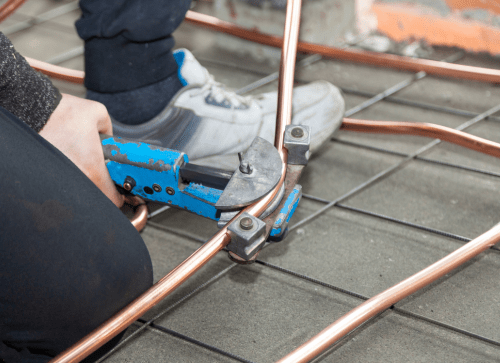

Step 5: Bend the Pipe

It’s time to bend the pipe after applying heat to the underfloor heating (UFH) pipe and achieving the desired temperature and flexibility:

- Ensure the pipe is at the correct temperature: Before bending it, confirm that it has reached the appropriate temperature, ensuring optimal flexibility for bending.

- Use a pipe bending tool or spring: To achieve a regulated and consistent bend, employ a pipe bending tool specifically designed for the diameter of the pipe.

- Position the bending tool or spring: Align the bending tool or spring with the marked bending point on the pipe.

- Apply gradual pressure while bending: Begin the bending process by slowly and gradually applying pressure to the pipe while firmly holding the bending tool or spring in place.

Step 6: Cool and Set the Bend

Once you have successfully bent the underfloor heating (UFH) pipe to the desired angle, allowing it to cool gradually is crucial:

- Allow for gradual cooling: As the pipe cools down, it will regain its rigidity and retain the shape of the bend.

- Avoid handling or moving the pipe: While the pipe is in the process of cooling and setting, it is crucial to avoid any unnecessary handling or movement.

- Monitor the cooling process: Keep an eye on the cooling process to ensure the pipe retains its shape and setting correctly.

- Verify the pipe is fully cooled and set: Before proceeding with any other installation or connection, ensure the pipe is completely cooled, and the bend has been set.

Step 7: Test the Bend

Once the underfloor heating (UFH) pipe has fully cooled and is set in its bent position, it is important to conduct a thorough test to ensure the bend is free from any kinks, deformities, or obstructions. Follow these detailed steps to test the bend properly:

- Run your hand along the bend: Gently run along the bend, feeling for abnormalities or inconsistencies. Pay close attention to the smoothness and continuity of the pipe’s surface.

- Ensure unrestricted flow: Check that the bend does not impede or restrict water flow through the pipe. Confirm that no tight bends or sharp angles could hinder water movement within the UFH system.

- Perform a trial run: Turn on the UFH system and observe the water flow through the bent pipe. Monitor the system for any signs of reduced water flow or pressure caused by the bend.

Installing Underfloor Heating

Underfloor heating pipe bending may appear difficult, but it is manageable with the correct equipment and methods. Using this step-by-step instruction, you can accurately bend the pipe to ensure good fit and effective heat distribution in your underfloor heating system. Remember to take your time, apply heat evenly, and utilise suitable support when bending.

Speak with a professional installation or contact JCW Underfloor Heating for advice and support if you have any questions or feel uneasy about the bending process. You may achieve a seamless and efficient underfloor heating installation in your area by taking the necessary precautions and paying close attention to detail.