14

Nov 2024

What Pipes Are Used For Underfloor Heating

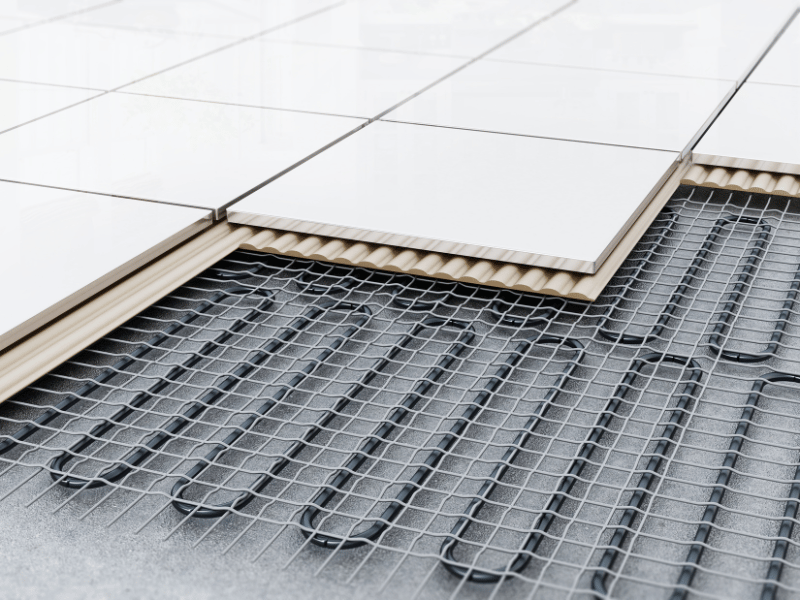

Underfloor heating systems rely on a network of pipes to circulate warm water beneath the floor surface, providing an even distribution of heat throughout the space. The choice of pipe material is crucial for the system’s efficiency, durability, and longevity. Here are the most common types of pipes used in underfloor heating systems:

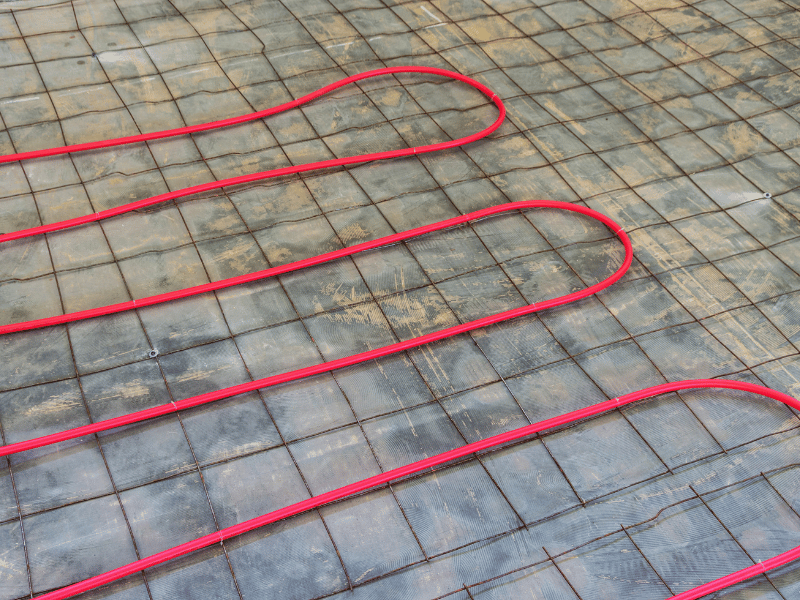

PEX (Cross-Linked Polyethylene) Pipes

PEX pipes are one of the most popular choices for underfloor heating systems. They are known for their flexibility, durability, and resistance to high temperatures. PEX pipes are easy to install, as they can be bent around corners and shaped to fit the layout of the room without the need for multiple joints. This reduces the risk of leaks. Additionally, PEX pipes have a high resistance to scaling and corrosion, making them suitable for long-term use in heating systems.

PERT (Polyethylene Raised Temperature) Pipes

PERT pipes are similar to PEX pipes but with slightly different properties. They are designed to withstand higher temperatures, making them a suitable option for underfloor heating systems. PERT pipes offer good flexibility and are easy to install, although they are generally considered to be slightly less durable than PEX pipes. However, they are still a reliable choice for underfloor heating, especially in residential applications.

PB (Polybutylene) Pipes

Polybutylene pipes, or PB pipes, are another type of plastic pipe used in underfloor heating systems. They are known for their flexibility, which makes them easy to install, particularly in complex or irregular floor layouts. PB pipes have good resistance to pressure and temperature changes, although they are less commonly used today compared to PEX and PERT pipes. Some older underfloor heating systems may still use PB pipes, but newer installations typically favour PEX or PERT.

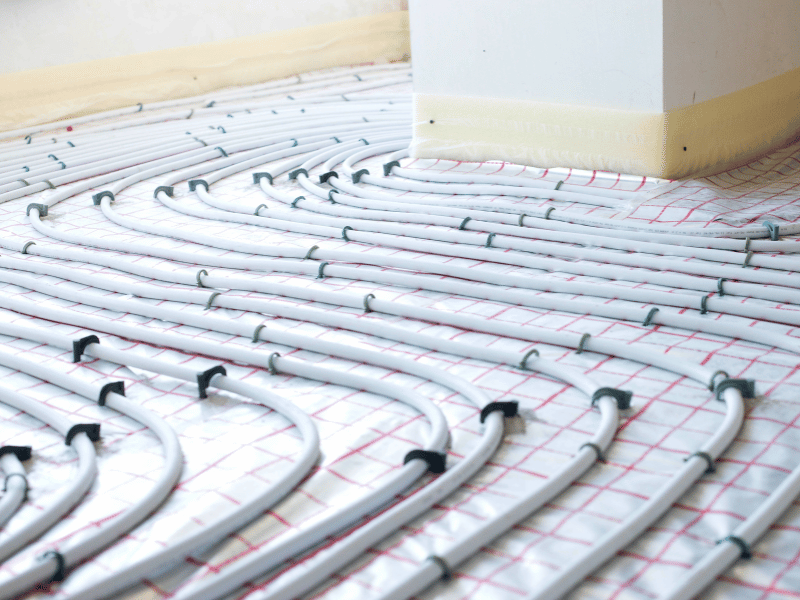

Aluminium Barrier Pipes (Multilayer Pipes)

Aluminium barrier pipes, often referred to as multilayer pipes, are composed of multiple layers, typically a combination of PEX or PERT and a thin layer of aluminium. The aluminium layer provides extra strength and helps to maintain the shape of the pipe, reducing the likelihood of kinking. The barrier also prevents oxygen from entering the system, which helps to prevent corrosion of the metal components in the heating system, such as the manifold. These pipes combine the flexibility of plastic with the durability of metal, making them a popular choice in underfloor heating systems.

Copper Pipes

While less common in modern underfloor heating systems, copper pipes are sometimes used, particularly in older installations. Copper is highly durable and has excellent thermal conductivity, which means it can transfer heat very efficiently. However, copper pipes are rigid and more challenging to install compared to plastic alternatives. They also require careful handling to avoid corrosion, particularly in systems where the water quality is not controlled. Due to these factors, copper is generally less favoured in contemporary underfloor heating installations.

Conclusion

The most commonly used pipes for underfloor heating systems are PEX and PERT pipes, due to their flexibility, durability, and ease of installation. Aluminium barrier pipes offer additional benefits in terms of strength and oxygen barrier properties, while copper pipes, although highly efficient, are less common in modern installations due to their rigidity and installation challenges. The choice of pipe material ultimately depends on factors such as the specific requirements of the installation, the type of floor covering, and the desired longevity of the system.

Upgrade Your Projects with Quality Underfloor Heating

Need dependable, easy-to-install underfloor heating systems for your next job? We offer high-performance products designed to keep your projects on track and your clients satisfied. Contact us today and benefit from our trade discounts and expert guidance.