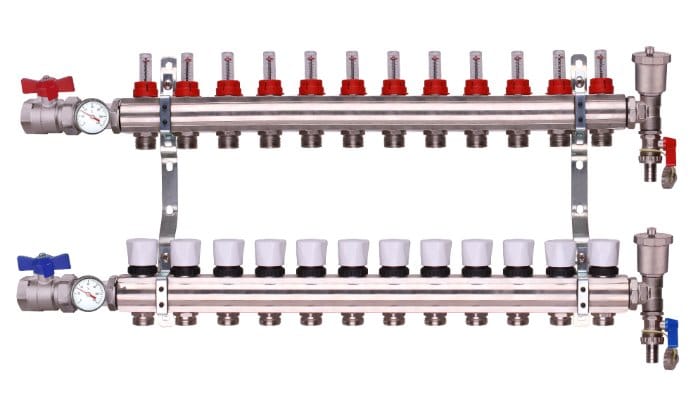

A manifold is a crucial component of an underfloor heating system, acting as the control centre for distributing heated water from the boiler or heat source to various circuits or zones. It typically consists of a flow manifold and a return manifold, mounted as a compact panel with valves, gauges, and flow meters. This setup ensures precise control over the water flow, maintaining even heating across all areas. A manifold is a well-organised network of pipes and valves, often enclosed for protection. Proper maintenance of this component is essential for efficiency and longevity, as it plays a central role in regulating heat distribution.

Regular Manifold Inspection

Maintaining your underfloor heating manifold is essential for ensuring both the longevity and efficiency of your heating system. Regular inspections are the first step in this process. It’s important to visually check the manifold frequently for any signs of wear, corrosion, or leaks. Pay particular attention to the valves and gauges, ensuring they are in good condition. Leaks around the connections and pipes, especially near the joints and valves, should be addressed promptly to prevent damage.

Balancing the Manifold System

Balancing the system is another crucial aspect of maintenance. Ensuring that the flow rates for each loop are balanced correctly is vital, as uneven flow can lead to inefficiency and inconsistent heating across different areas. Adjusting the flow meters as needed helps maintain a uniform temperature throughout your heated space. Additionally, monitoring the pressure gauge on the manifold is important; the pressure should remain within the recommended range, typically between 1 and 2 bar. Low pressure could indicate a leak, while high pressure might suggest blockages or an overfilled system.

Manifold Cleaning

Keeping the manifold clean is also essential for optimal performance. Regularly clean the manifold body to remove dust and debris, which can lead to overheating or reduced efficiency. If your manifold has a built-in filter, ensure it is cleaned regularly to prevent blockages and maintain smooth water flow through the system.

Bleeding the System

Air trapped in the system can cause uneven heating and reduced efficiency, so it’s important to bleed the system periodically to remove any air pockets. This can usually be done using the air vents located on the manifold.

Manifold Servicing

Scheduling annual servicing with a qualified technician is advisable. During these visits, the technician can check the overall system, including the manifold, for any potential issues. They can also flush the system if necessary to remove sludge or deposits that can build up over time.

Monitoring and Control

It’s important to ensure your thermostats are correctly set and functioning. Incorrect settings can lead to the manifold working harder than necessary, reducing its lifespan and efficiency. Over time, deposits can build up in the system, reducing efficiency. Regular flushing of the system, typically every 5-10 years, can help maintain optimal performance.

Protective Measures

Ensuring that all pipes leading to and from the manifold are properly insulated is crucial. This helps maintain the desired water temperature and reduces the workload on the system. Additionally, in colder months, it’s important to ensure that the manifold and associated piping are protected from freezing, which can cause serious damage.

Documentation

Finally, keeping a detailed log of all maintenance activities, including inspections, cleaning, and professional servicing, is essential. This helps track the system’s condition and identify any recurring issues.

By following these maintenance steps, you can ensure that your underfloor heating manifold operates efficiently, providing consistent warmth and lasting for many years. Regular attention to these areas will also help prevent costly repairs and extend the life of your entire underfloor heating system.